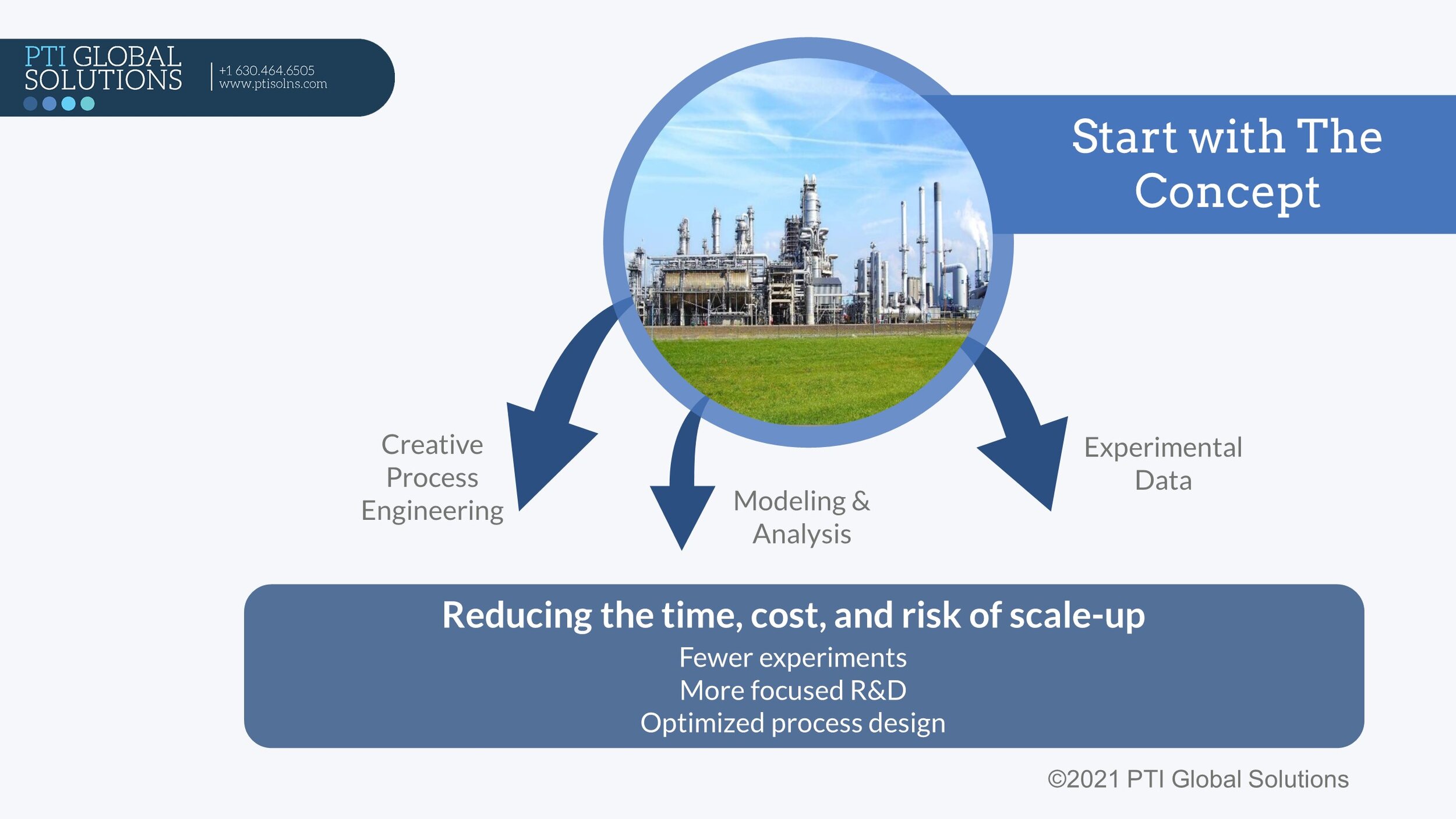

In my introductory article on this topic (Practical Technology Scaleup) I wrote about the benefit of drawing on Creative Process Engineering, Modeling & Analysis, and Experimental Data to develop a solid Process Concept to drive the scale-up effort--reducing risk and optimizing the economics of a sustainable technology.

Creative Engineering, like Creative Accounting, may be an oxymoron or have negative connotations, but in my experience, it is critical for first of its kind technology. Creative process engineers understand commercial plant design and can also deal with the ambiguity that is common with any new technology. This creativity enables the engineers working closely with the science experts to develop the process concept, establish the material balance, and make key process design decisions to set the framework for the evolving novel technology. These decisions fall into categories such as:

· Product Requirements. Product quality. Waste vs Byproduct. Batch vs Continuous.

· Catalyst: Composition. Biological vs Thermochemical. Size/shape. Heterogenous vs Homogenous.

· Major Unit Operations. Reactor concept. Feedstock processing. Separation processes.

· Major Equipment. Standard or Custom. Pump/Exchanger/Compressor type.

· Design Conditions. Temperature. Pressure. Product Specifications.

The challenge of translating discoveries from the lab into viable process flowsheets has been described by Douglas[i] to require assumptions 1) that fix parts of the process flowsheet 2) that fix some of the design variables and 3) that fix the connections to the environment. Douglas estimates that more than one million process flowsheets can be generated just from the varied assumptions associated with the first process flowsheet. Clearly it is not feasible to evaluate all of these alternatives. The good news is that we can just as quickly reduce the number of alternatives to a more manageable number but need good engineering judgement to make decisions with relatively little information. This is where the Creative aspect of Process Engineering is critical.

In practicality I find it is best to identify the reactor concept and separation scheme that are the best options, and then build the flowscheme around these. Often, this is a case of screening out the ‘bad options’ resulting in several process concepts that make sense. We can then define the data needed by Experimentation and Modeling & Analysis to refine our choices to the best option. These areas will be explored in future articles.

[i] Douglas, J.M. “A Hierarchical Decision Procedure for Process Synthesis”, AIChE Journal, March 1985, Vol. 31. No 3, pp 353-362.